How to Thread a Brother Sewing Machine? | Palmgear

by William Sanders

Are you someone who is thinking of taking up sewing as a leisure time activity? Or trying to learn the best way to thread a brother sewing machine? Well, if you happen to be any of those mentioned above, then you are in the right place because any information you need for the threading task, we have it here for you.

So, if you want to know all the ins and out of threading a brother sewing machine, then keep reading; you will find all the information you might need right here.

Contents

How to Thread a Brother Sewing Machine?

The whole process will be broken down into three parts. Each of the part is essential to reach the final result you want to get.

Winding the Bobbin

Let’s learn how to wind the bobbin.

Step 1: The spool has to be positioned

You have to insert the spool on the spool pin at the top of the sewing machine. This step is not complicated at all; you will just have to put it in place. While starting off, remember to have the sewing machine turned on, as the process will not work.

Also, note down that if you have already wounded your bobbin, then there is no need to follow the first few steps of the process. You came move right ahead to the other sections.

Step 2: The thread needs to be wrapped

Now, on the other side of the machine, there is a bobbin tension disc, you have to bring the tail of the thread and then wrap it around the disc. Before you wrap it, make sure the thread unwinds in a clockwise direction, if not, then you have to reposition it on the spool.

While wrapping, the tread will first start from the left of the disc and then will be brought around to the front of the machine.

Step 3: The thread has to be drawn into the bobbin

You must bring forth the tail end of the thread and put it through the hole of the bobbin. The thread has to move from the inside of the bobbin to the outside. And make sure you draw about 2 to 3 inches of the thread through the hole.

Step 4: Lockdown the bobbin and wrap the thread around

At this stage of the process, you will have to secure the bobbin into place so that it does not come off while you work. To lock it in place, you will have to place the bobbin in the shaft and slide it to the right. Keep in mind that the side with the thread has to face up.

Wrap the thread around the bobbin by holding on to the tail end of the thread and pressing on to the foot controller. Keep doing so for as long as it takes you to fill the bobbin up completely with the thread. Your machine will automatically stop when the bobbin has been filled.

All you have to do is detach the thread wrapped around the bobbin from the spool using a scissor.

Step 5: The bobbin has to be removed

Once the bobbin is full and you have already cut off the connecting thread, it is now time for you to remove the bobbin from its place. To do this, you have to do some reverse action from what you did to secure it to place.

Move or slide the bobbin from the shaft to the left, by doing so, you will be unlocking it from the place. All you have to do now is lift it, and it will come right out. With that we end this part of the process, we can now move on to the next one.

Threading the Needle

Here’s the step-by-step guide on threading the needle.

Step 1: The thread take-up lever has to be raised

To the right side of the sewing machine, you will see a wheel that has to be turned in an anti-clockwise direction until the thread take-up lever has reached the highest position. Remember that you cannot rotate it in a clockwise direction or away from you as it will damage the machine.

Another tip to keep in mind here that you are raising the take-up lever is to turn the equipment off to avoid any kind of injury you might suffer from.

Step 2: The spool of thread has to be thrown, and the thread has to put in the right place

Your spool should already be on the pin at the top of the sewing machine if you have started off by winding the bobbin if it’s not then you will have to set it right and then make sure the threads come out of the spool in a counter-clockwise direction.

To draw it through the right channel, the thread has to be drawn out and pulled across the top part of the machine, through the thread guide. And then finally, the tail of the thread can enter into the channel it is supposed to go through. So, it basically goes right down along the slit at the side of the sewing machine.

Step 3: The thread has to be wrapped around the tension disc

Once the tread goes through the channel, take the tail and wrap it around the tension disc. It is between the channels that run by the side of the brother sewing machine. To secure the thread around, you have to go from right to left.

Once it is wrapped nicely, you have to pull out more thread from the spool for the next step of the process.

Step 4: Hook the thread through the take-up lever

There are two channels that run along the side, you already put the thread through the right channel and wrapped the thread around the tension disc. Now you have to take the thread up along the left channel. Bring it all the way up so you can easily hook the thread to the take-up lever.

You should not face any trouble hooking the thread to the take-up lever as it should be completely visible to you since you brought it all the way up. After this step, give the thread a little tug to see if there is any resistance while getting more of the thread out of the spool.

Step 5: The thread has to be hooked to the last thread guide

There is a thread guide place right above where the needle is situated. Once you bring the thread through the left channel, you must hook the thread through the last guide before you can move ahead with the rest of the steps. When it has been secured properly, you can move on.

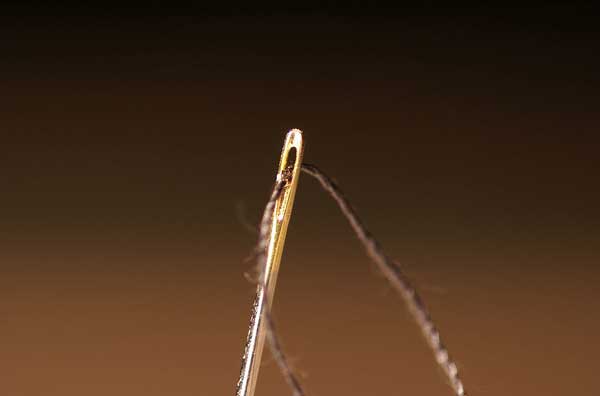

Step 6: The thread goes through the eye of the needle

What you have to do at this stage of the process is to put the thread through the eye of the needle. You have to take the needle from the front of the machine towards the end to get the job right. Make sure the end of the thread you are using is not frayed as you will have a tough time getting it through the hole.

So, if it is frayed, just take a scissor and cut the end of it off. Once it goes through, pull the thread so the there is a two-inch extension.

The Process to Load and Draw up the Bobbin

Below, I’ll show you how to load and draw up the bobbin.

Step 1: Place the bobbin inside the socket or hole by the needle

So, right in front of where the needle is, you will see a socket, that is where the bobbin is going to go. But before you put that into place, about 4 inches of the thread has to be pulled out. There is a bobbin case inside, that is where you have to place the bobbin.

Make sure the bobbin is placed in a way so that the thread comes out in an anti-clockwise direction, just as it did with the spool of thread.

The direction is important as else the whole thing is going to be messed up when you do start sewing with the machine. You will have to redo it all over again. So, it is better to keep this in mind and get it right the first time.

Step 2: Hook the thread of the bobbin to the guide at the base and then through the slit

Now, at the base of the sewing machine right by the hole you popped the bobbin into, there is a hook. You will have to wrap the thread around that hook or clip. Just as you did with all the other clips and thread guides, you have to do the same with this one, so it should not be confusing.

Then pull off the thread-like you did with the thread from the spool to check whether there is any type of resistance. Once you’re sure there is nothing stopping the thread, you will have to guide the thread through the curved socket at the base of the machine located beside the socket.

Now all you have left for this step is to pop the lid into place, and then you’re ready for the next one.

Step 3: The needle needs to be cycled once

When your bobbin is secured to its place, and the lid has been shut, you now have to pull the thread from the bobbin to the needle and attach the thread from the spool and the bobbin. In order to do so, you will have to cycle the needle.

Bear in mind that your sewing machine should be off at all times during this part of the process as if you somehow stepped on the foot control, then the needle might end up going right through your finger.

So for the cycle, you have to manually work the needle using the same wheel or knob as the back of the machine. When you turn it towards you, the needle will go down to its base automatically. And then it will come back up to the highest position, which it was in previously.

Step 4: Catch the loop you just created

When you cycled the needle, you created a loop, that was your goal. Now you have to catch it.

You will have to pinch it with your thumb and index finger, and in the process, you will break the loop. Upon which, you will find two different tails of threads, one of which belongs to the upper thread and the other one came from the base of the sewing machine.

Step 5: Both threads have to be straightened

At this point, you have two tails of threads, both of which you have to pull on until you have about 6 inches of each extended out. The tails should go behind the machine. Make sure the placement of the two threads is right, the upper thread goes in the middle of the presser, while the lower thread goes behind it.

Step 6: Go through the manual

The very last step before you start sewing is to recheck with the instruction manual you have been provided with. Make sure you have placed the upper and the lower thread the way it should be. If you see it is, then you are good to go and can start the project you have.

And with that, you are done threading the brother sewing machine. There are many steps, some that are smaller than the other. But each and every one of them is equally important. If you miss something out, then you will not be able to get the result you are looking for.

Conclusion

When you read all the steps and the instructions, it might seem a bit complicated or lengthy, but when you actually start the process, you will see that the entire job should not take you more than a few minutes.

Happy sewing!

|

|

|

|

|

|

|

|

About William Sanders

William Sanders was born and raised in California. After receiving his Master’s degree in information science from San Diego State University, he started working as a city councilor. In his spare time, William enjoys playing best-selling MMORPG games such as World of Warcraft and Fnal Fantasy, where he often takes on the role of guild leader with hundreds of players collaborating for success under his leadership. William is also a regular contributor to some popular magazines such as San Jose Mercury News, Gleanster Research, and Palmgear.

Leave a Reply

You can get FREE Gifts. Or latest Free phones here.

Disable Ad block to reveal all the info. Once done, hit a button below

|

|

|

|