How To Print Onto Plastic Surface? Cards, Bags etc.

by Alice Davis

If you're having a hard time figuring out how to transfer visuals or any other type of design onto plastic surfaces, you'll find this guide helpful.

Plastic has become increasingly popular among businesses. And as such, it has led to the need to print on the plastic surface to embed the business/product details.

Luckily, there are various methods of printing on cards, bags, and other plastic surfaces. But the type of plastic material in use will determine the most appropriate printing method.

Contents

In this guide, we'll dive into more details about printing on plastic surfaces.

The different types of plastic materials available

As a business that plans to print on plastic products, it's essential that you understand the different types of plastic materials available on the market and their printability. This will help you pick the right material that will give you a smooth printing experience.

The most popular types of plastic you can find on the market today include:

Polystyrene

If you want a plastic material for making signage, packaging, and other cost-saving applications, polystyrene is a great choice. The material is recyclable and device-friendly, which makes printing high-resolution designs on it super-easy for you. But keep in mind that this plastic isn't foldable and might become brittle with time. Also, it's not approved for direct contact with edible goods.

Polypropylene

This material finds wide usage in the manufacturer of polyethylene bags, tags, and labels. The material has highlights such as easy foldability, recyclability, and lightweight design. Not to forget, it's safe for direct contact with food. However, these sheets are usually difficult to bond and are not as tear-resistant. They're ideal for printing simpler designs.

Polyester

Also referred to as Polyethylene terephthalate or PET, polyester is a great material for making outdoor-friendly resources like nameplates sailboats masts. The material feels incredibly tough and stable and is machine-friendly. But keep in mind that it might cost you more than other plastics and doesn't offer a lot of flexibility.

Polyvinyl Chloride (PVC)

This is simply rigid vinyl and boasts its place as one of the easiest to print plastic materials. It's incredibly durable and machine-friendly. And offers high resistance to UV degradation. Unfortunately, it has limited flexibility and is not recyclable.

The different printing methods for plastic surfaces

As there are many plastic materials available, so are the printing methods. In this section, we'll be looking at the various printing methods you can use to transfer your designs onto plastic surfaces.

Inkjet printing

This is one of the most effective ways of printing surfaces. It lets you easily transfer high-quality images with full color onto a variety of plastic materials. since it requires minimal setup, this method is suitable for doing one-off prints or short production runs.

The special ink used here is dried by evaporation, making it possible to use this method to print onto just anything, including printing on sticker, wide-format self-adhesive vinyl rolls, large, rigid plastic items, and more.

Just like the inkjet office printer, the inks needed for this method are quite expensive-meaning long production aren't cost-effective.

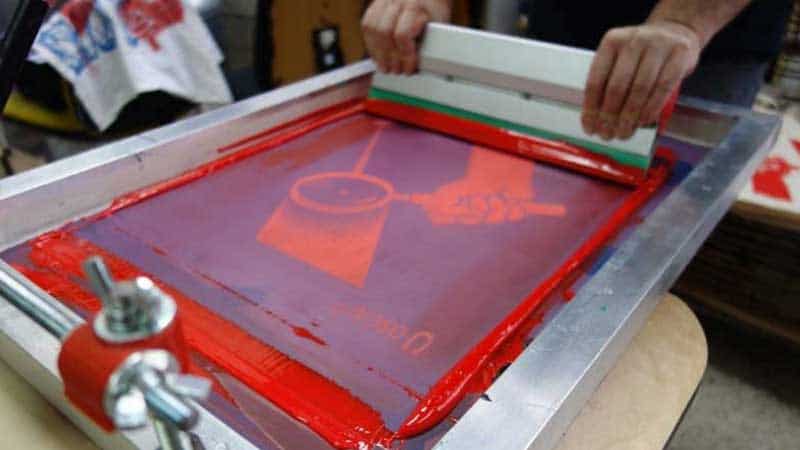

Screen printing

The screen-printing is the opposite of ink jet printing; it's a traditional method, unlike ink jet, which is a digital method. Despite the difference, screen-printing also makes a great option for various plastic printing applications.

The method involves using blocking stencils on a screen (a fine silk mesh) through which you squeegee the ink to transfer your design to the plastic surface.

The ink is then exposed to high powered YUV light to dry it completely, leaving behind a durable design with vibrant colors.

Thermal transfer printing

You can also apply the thermal transfer printing method for transferring your visuals onto plastics. For this method, you'll need to sue a special coating on your substrate…or use specialized plastic to enable the thermal printer to work.

While still on the thermal aspect, you can also use a heat press machine to transfer your designs to plastic items such as mugs, bags, cards, and so on. Check this list of the top heat press reviews for some top models that will let you print on such items easily.

Laser printing

You can use your standard office printer to easily print onto certain plastic surfaces. This method calls for extra caution, though. You'll need to ensure your substrate is laser compatible because the printer's fuse unit tends to get really hot and can end up melting your plastic sheets inside the printer.

Other effective plastic printing methods include flexo, pad, and UV litho printing methods. However, these methods require you to have more space, operators, equipment, and an extended setup time-making them best suited for commercial print shops.

The good thing about these methods is their ability to produce detailed, full-color prints such as product labels or flat surfaces such as printed storefront design.

Final Verdict

There are many effective methods of transferring designs onto your plastic products. The most important thing to remember here is the type of plastic material you're using and whether the printing method you chose is compatible with the material. The most popular printing methods for most businesses include digital inkjet printing and the traditional screen printing method. Both methods are simple to apply and can work with a wide range of plastic surfaces.

|

|

|

|

|

|

|

|

About Alice Davis

Alice is a writer who lives in the City of Long Beach. She has a husband, an exceptionally small chihuahua, and 15-pound Maine Coon. Alice got her bachelor of science in biological science from UC Berkeley. Now, she likes writing about a lot of things; including but not limited to technology reviews, science stuff, and anything food-related.

Leave a Reply

You can get FREE Gifts. Or latest Free phones here.

Disable Ad block to reveal all the info. Once done, hit a button below

|

|

|

|